Key Ingredients

Free from parabens, sulfates, and phthalates. Cruelty-free and vegan

- Shea Butter: Provides deep hydration and helps to keep lips soft and smooth.

- Jojoba Oil: Natural oil that moisturizes and conditions the lips.

- Vitamin E: An antioxidant that helps to protect and nourish the lips.

- Beeswax: Creates a barrier to lock in moisture and provides a smooth application.

- Castor Oil: Adds shine and helps to keep the lipstick creamy and easy to apply.

Key Features

Our creamy matte lipstick is made with high-quality ingredients to ensure a safe and enjoyable experience:

- Vibrant Color: Rich, highly pigmented formula provides bold, vivid color in just one swipe.

- Creamy Texture: Smooth, velvety texture glides effortlessly onto the lips without tugging or dragging.

- Long-Lasting Wear: Stays put for hours, ensuring your lips look flawless throughout the day.

- Moisturizing Formula: Infused with nourishing ingredients to keep your lips hydrated and comfortable.

- Wide Shade Range: Available in a variety of shades, from classic reds and pinks to trendy nudes and bold berries, to suit every skin tone and occasion.

- Matte and Satin Finishes: Choose from an elegant matte finish or a luminous satin finish to match your mood and style.

More Formulation

Lipstick formulations can vary widely based on the desired characteristics, ingredients, and benefits. Each formulation has its own benefits and can be chosen based on the desired look, feel, and additional benefits like moisturization or long-lasting wear.

Matte Lipstick: Matte lipsticks have a non-glossy or low-luster finish, offering intense color payoff and long-lasting wear.

Cream Lipstick: Cream lipsticks have a smooth, moisturizing texture that provides medium to high coverage color, suitable for everyday wear.

Satin Lipstick: Satin lipsticks fall between matte and glossy, offering medium coverage color with a slight luster.

Glaze/Gloss Lipstick: Glaze or gloss lipsticks contain oily and shiny components, providing transparent to translucent color and high luster to the lips.

Lip Stain: Lip stains offer long-lasting color but relatively less coverage, often needing to be combined with other types of lipsticks for a more complete effect.

Sheer Lipstick: Sheer lipsticks provide a light, almost transparent coverage, usually used to enhance natural lip color or as a base for other lipsticks.

Tinted Lip Balm: Tinted lip balms combine the moisturizing properties of lip balms with slight color, offering natural lip color and hydration.

Liquid Lipstick: Liquid lipsticks usually have high coverage and long-lasting wear, with textures ranging from matte to high gloss.

Lip Liner: Although not a lipstick, lip liners are often used to define lip shape or as a base for lipstick, helping to improve the longevity of lipstick.

Lip Gloss: Lip glosses are typically used to add extra shine and volume to lipstick or can be worn alone to provide light color and luster.

More Finish

Lipstick can come in various finishes,each finish can create a different look and feel, and the best one for you depends on your personal preference and the occasion.

“lipstick finish” refers to the effect that a lipstick leaves on the lips after application. Here are some common types of lipstick finishes:

Matte: A matte finish is non-glossy or flat, providing a rich, opaque color with a smooth, velvety appearance.

Cream: A cream finish gives the lips a moist, creamy look with medium-to-full coverage that is both hydrating and comfortable to wear.

Satin: A satin finish offers a balance between matte and glossy, with a soft, subtle luster and medium coverage that is both elegant and long-lasting.

Glaze/Gloss: A glaze or gloss finish provides a high shine and can offer sheer to moderate color payoff, often used for a plumping effect or over another lipstick for added dimension.

Sheer: A sheer finish is translucent to slightly opaque, offering a lightweight color that enhances the natural lip while providing a subtle wash of color.

Frost: A frost finish contains flecks of shimmer, creating a sparkling or metallic effect on the lips, usually paired with lighter color options.

Lustre: A lustre finish is somewhere between sheer and cream, providing a hint of luminosity and a touch more color than a sheer finish.

Creamy Matte: A creamy matte finish combines the opaque color payoff of a matte with the comfortable feel of a cream finish, offering long-wear without the typical dryness of a matte lipstick.

Liquid Suede: A liquid suede finish provides a velvety matte look with the ease of application of a liquid lipstick, giving a futuristic matte effect that is not drying.

Metallic: A metallic finish offers a highly reflective, mirror-like shine with intense pigmentation, suitable for making a bold statement.

Pearl: A pearl finish has fine pearlescent particles that provide a subtle shimmery finish, adding a soft, illuminating touch to the lips.

More Textures

- Smooth: These lipsticks glide smoothly on the lips, providing an even application.

- Creamy: These lipsticks have a creamy texture, offering a moisturizing feel.

- Dry: These lipsticks, often matte lipsticks, may feel dry on the lips but provide a long-lasting finish.

- Sticky: Some lipsticks, especially glosses, may have a sticky texture.

- Lightweight: These lipsticks, often lip stains, provide color without a heavy feeling on the lips.

Flavor

Free from parabens, sulfates, and phthalates. Cruelty-free and vegan

- Watermelon, strawberry, peach, mint,rose, vanilla etc.

Filling Color

Free from parabens, sulfates, and phthalates. Cruelty-free and vegan

- Send us your color picture

- we offer color chart

- choose from Pantone colors

Packaging

Custom Cosmetics Business For Over 10 Years

- Inner Contanier : Lips , Eyes ,Faces

- Outter packaging : Color Box

- Label and shrink film etc.

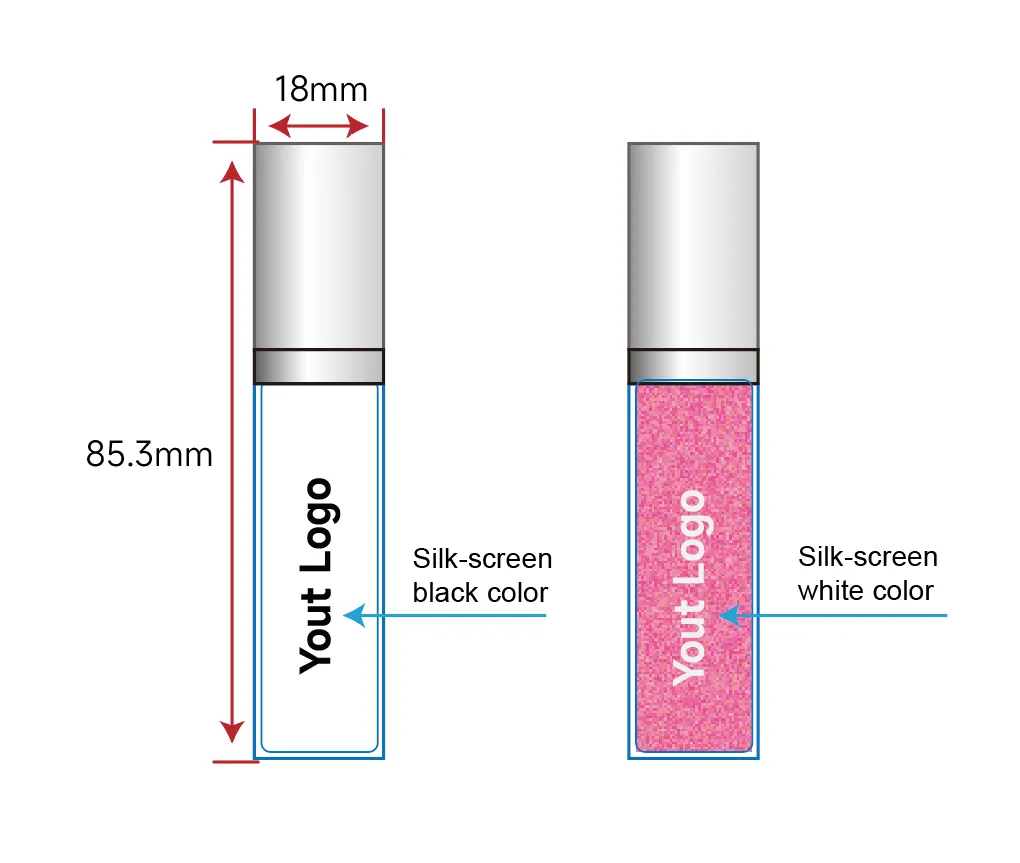

Primary Inner case Packaging

Customized! can make the packaging to any colors, or make shiny finish, or matte finish etc

- Printing Methods:

Silkscreen Printing:

Hot Stamping:

Digital Printing:

The choice of technique depends on the design and the material of the container.

- Printing Materials: Common materials include plastic, glass ,metal

- Surface Treatments:

- Spraying: This is a common surface treatment technique that can change the color and texture of the container. Spraying can be transparent or opaque, and the finish can be smooth or matte.

- Electroplating: This technique involves depositing a thin layer of metal onto the container surface, creating a mirror-like glossy effect.

- Heat Transfer: This technique can create complex patterns and designs on the container surface. It uses heat to transfer pre-printed images onto the container.

- UV Coating: This coating can provide additional protection against scratches and wear, while increasing glossiness.

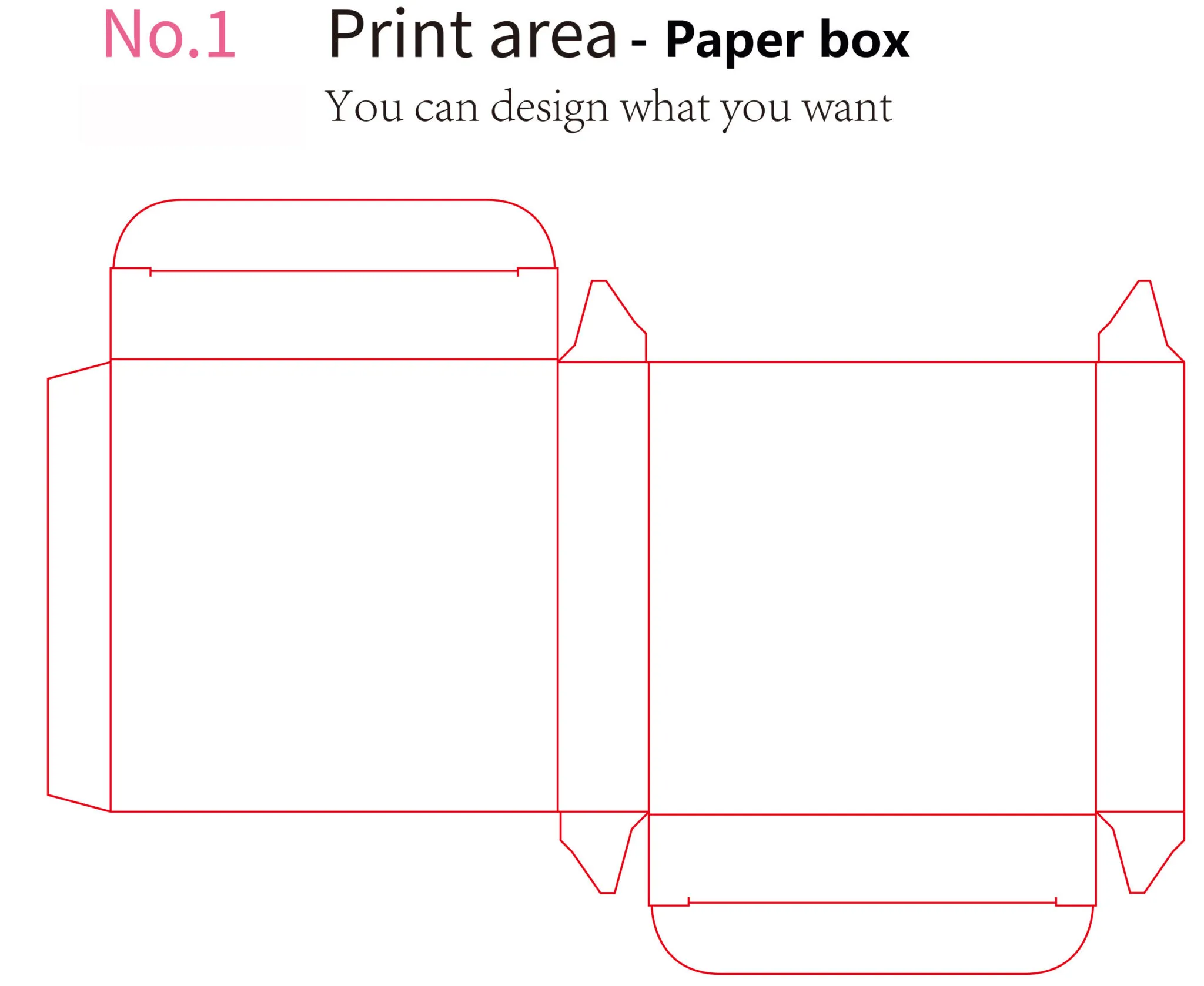

Secondary Color Box Printing

Color box printing refers to the process of printing multi-colored designs on cardboard or other packaging materials to create attractive and protective packaging boxes. It includes various stages such as design, printing, and surface finishing, each vital for ensuring high-quality output.

- Printing Methods:

Offset Printing:

Flexographic Printing:

Digital Printing: - Printing Materials: High-quality paperboard (like white cardboard, gray board, and coated paper) and eco-friendly inks are used to ensure print quality and environmental compliance.

- Surface Finishing 1:Lamination: Covering the printed surface with a plastic film (glossy or matte) to enhance durability and appearance. 2:Hot Stamping (Foil Stamping): Adding metallic foil (gold or silver) to specific areas to create a luxurious and eye-catching effect. 3:UV Coating: Applying a UV-cured coating to enhance gloss and scratch resistance. 4:Embossing/Debossing: Creating raised or recessed designs to add tactile and visual interest. 5:Spot UV: Applying UV coating to specific areas to create contrast and highlight certain parts of the design

- Die-Cutting 1: Die-Cut Plate Production: Creating a die-cut plate based on the structural design to cut the printed sheets into the desired shape. 2:Die-Cutting and Creasing: Using a die-cutting machine to cut and crease the printed sheets, making them easy to fold into boxes.